BONDING

Room temperature wafers bonding equipment and service

- Home designed plasma assisted UHV vacuum system for wafer bonding

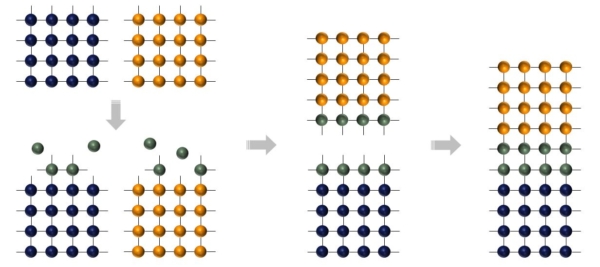

- Surface of wafers are activated using plasma source in the high vacuum chamber

- Wafers are pressed inside the vacuum

- Active atoms on the surface of wafers diffuse and form an atomic diffusion bond

- Bond strength is so high that it is impossible to separate the wafers without breakage

- Materials with different thermal expansion coefficients can bond to each other since no heating is required

- Brittle materials such as InP or GaAs can bond to Silicon or other materials since no high forces are required

- No intermediate layer is required so the bond interface is transparent to light and heat.

Applications

- Transparent optical bonding

- Bonding of photodetector and various optical elements on different substrates

- Wafer level packaging

- MEMS encapsulation and device fabrication

- Functional wafer fabrication such as lithium niobate thin films on Silicon

Features

- No intermediate layers

- No heating is required

- No high force or high pressure is required

- Very strong bond higher than yield strength of many materials is obtained

- Dissimilar wafer bonding up to 4″ wafers

Example Substrates

- GaAs, LiNbO3, Quartz, Silicon, GaN, Germanium, Saphire

- Metal to metal surface bonding

- Oxide to metal bonding

- Semiconductor to semiconductor bonding

- Semiconductor to oxide bonding

- Oxide to oxide bonding

Requirements

| Parameter | Substrate I | Substrate II |

|---|---|---|

| Material | Silicon, Lithium Niobite, Quartz, GaAs, InP | Silicon, Lithium Niobite, Quartz, GaAs, InP |

| Diameter | 25 mm, 100 mm | 25 mm, 100 mm |

| Thickness | 100 µm to 1 mm | 100 µm to 1 mm |

| Surface Roughness | <0.5 nm | <0.5 nm |